The oil and gas industry is rife with safety challenges. This is the nature of the work, which often places human beings in close contact with volatile chemicals and dangerous environments. As a result, 489 people lost their lives in oil extraction-related incidents between 2013 and 2017. Now, the industry strives to do better, and this means collaboration between human effort and new technologies.

Right now, technological innovation — particularly within the realm of AI — has transformed what is possible in workplace safety. Meanwhile, human practices can maximize the success of these risk-reducing technologies to produce safer environments. Where human and machine perception connects, better business is possible. This means healthier workers, reduced liability, and avoidance of tragedy in the course of oil extraction.

Reducing safety risks requires a comprehensive view of the challenges and the implementation of more transparent tools. By exploring these subjects, industry leaders may literally save lives. Strike a balance between proper training and tech utilization to achieve greater safety on the job.

Safety Risks in the Oil Industry

Unfortunately, the occupational hazards of oil and gas extraction are disproportionately high. With as many deaths occurring in the industry between 2008 and 2017 as there were U.S. soldier fatalities in Afghanistan, safety is a real and pressing concern. Additionally, a majority of workers in the industry are reportedly considering a change, either towards renewables or out of the industry altogether. Facing an imminent labor shortage, industry leaders cannot afford to neglect safety risks.

These hazards occur by the nature of the work. The industry is vast and the materials workers interact with often require protective equipment. In the course of oil and gas extraction, some of the most common occupational risks include:

- Vehicle collisions in the oil supply chain

- Workers struck or caught by vehicles or equipment

- Explosions and fire from volatile chemicals

Accidents like these can lead to traumatic injury and even death. To protect your workforce, a comprehensive effort to mitigate risks must take place.

But how can industry leaders and safety managers combat accidents and human error? Mistakes will always occur because to err is human nature. The answer to enhanced safety in oil production and supply must then be to fill safety gaps with cutting-edge technologies capable of protecting workers.

Human Safety Efforts

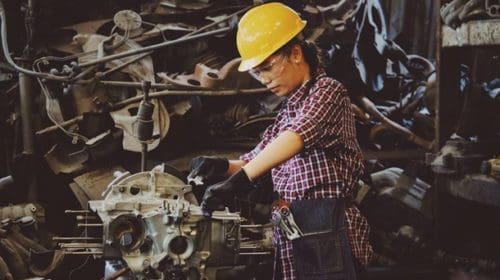

First, we have the human component of workplace safety. These are the best practices needed to maintain an accident-free environment to the best of human ability. It’s all about education and supporting workers with the resources they need to stay safe and help others stay safe.

For example, eye hazards are common in oil production and extraction. Protecting your vision requires not only protective equipment like safety goggles but the knowledge of when to use them and how to wear them properly. Education and rule enforcement is essential to safety efforts no matter the technologies you employ to supplement them.

Reducing safety risks means developing a self-policing system for workers to follow. These are some ideas for producing such a safety-conscious process:

- Invest in regular worker safety education.

- Put up clear and ADA-compliant signage.

- Tie safety metrics to bonuses and incentives.

- Maintain an open and non-retaliatory issue-reporting policy.

With these best practices, workers are better positioned to support each other in staying safe. Incentives for following safety regulations help workers keep those regulations in mind. Meanwhile, an open-door policy for reporting safety hazards without retaliation against the whistleblower makes for a safer environment.

No matter what other technology you employ in oil extraction and supply, ensure that all workers are adhering to safety procedures at all times. Only then can technology be truly effective in covering safety gaps.

Cutting-Edge Safety Technology

Fortunately, safety technology has come a long way from simple protective clothing and gear. These days, artificial intelligence is the word in workplace safety due to its ability to assess data in real-time and empower more accurate risk avoidance systems. This technology is providing new layers of refinery safety through transparency and machine learning.

That’s because oil and gas 4.0 includes the Internet of Things (IoT), 5G connectivity, and AI-powered analytical tools that produce insights from collected data. From here, safety managers can monitor risk areas with computer vision, integrate better collision avoidance systems, and even automate the most dangerous of tasks.

Risk management is one of the top trends in AI because of the usefulness of this tech in preventing accidents. These are just some of the ways cutting edge safety tech reduces risks:

- Analytics software judges acceptable risk thresholds.

- Predictive analytics identify areas of risk.

- AI systems assess probabilities and outcomes.

- Claims management systems produce alerts.

- IoT networks and smart devices monitor threats.

Smart devices capture data about environments through sensors or cameras. Then, this information is processed through an AI, which alerts workers to any potential safety threats. Imbedded in heavy machinery, this tech has the potential to eliminate many of the common occupational hazards inherent in the oil industry. In the future, fully automated trucks may be responsible for transporting oil, mitigating the risk of human error on the road.

Reduced Safety Risks People and Technology

Reducing safety risks in the oil industry shouldn’t just be a matter of compliance. You can advance worker safety through a comprehensive effort on the part of both people and technology. This begins in worker education and continues with the application of smart tools for sensing, predicting, and avoiding dangers in the workplace.

Only through a joint effort from workers and data systems can optimal safety be created within oil production. Consider these best practices and technologies when optimizing the safety of your own ventures.

Indiana Lee lives in the Northwest and has a passion for the environment and wellness. She draws her inspiration from nature and makes sure to explore the outdoors regularly with her two dogs. Lee also has experience in owning and operating her own business. Feel free to follow her on Twitter @indianalee3.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.