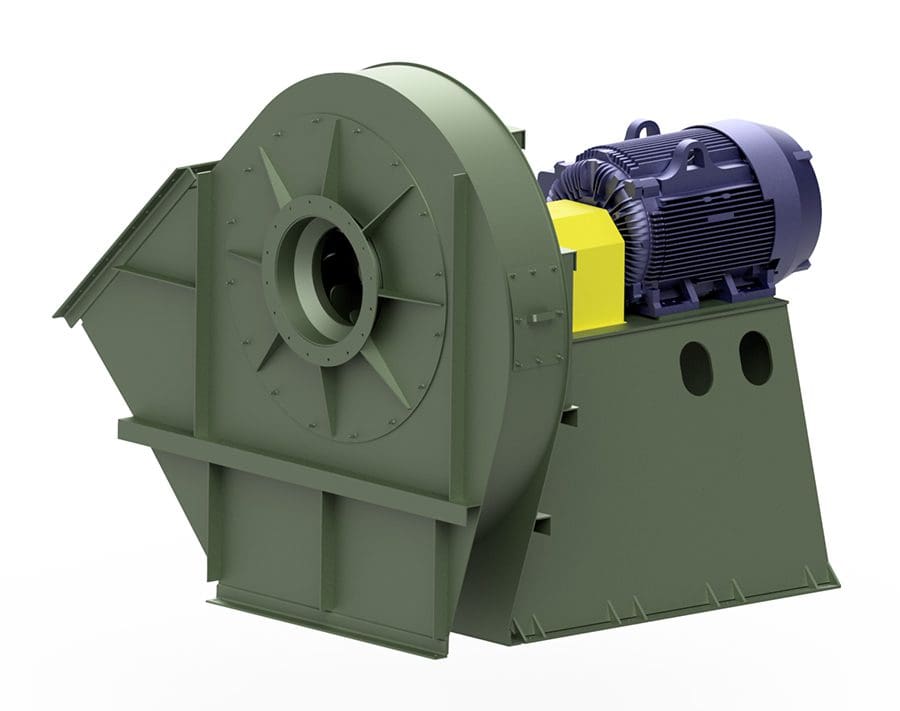

WILLOWBROOK, IL, — The New York Blower Company has expanded its line of high pressure backward inclined fans with the release of BC-2200 fans. It is ideal for high-flow, high-pressure applications of both clean air and light particulate-laden/moist air gastreams including thermal oxidation, steel plants, combustion air, nuclear, ethanol, refineries, dust/fume control, quench cooling and glass production.

“The BC-2200 is designed to accommodate a wide assortment of industrial process applications ranging from processing steel and glass to providing combustion air for boiler and burners” says David Maletich, Vice President of Marketing at New York Blower. “Users need a fan that can be adapted to the requirements of their specific application. This unique fan can be designed to handle temperatures from -50°F. to over 1000°F. and can be constructed using a variety of special alloys, such as Hastelloy, Inconel, or Carpenter 20, to meet application demands.”

The fan reaches a volume of 60,000 Cubic Feet Per Minute (CFM) [(101,940 m3/hr.)] and can be customized per customer specifications. It is available as standard in both belt-drive (Arr. 1) and direct-drive (Arr. 8) configurations, with arrangements 4, 3S1 and 7S1 available on request. BC-2200 fans are easily selected based on required operating capabilities using nyb’s online fan selection program, Fan-to-Size.

Standard design features allow for pressures to 65” wg (16,175 Pa) and temperatures to 800˚F (427˚C). Higher pressures and temperatures are available with modifications and/or special construction, such as using alloys or special coatings, heat fan construction, and spark resistant construction (SCR). To make maintenance easier, two types of split housing options allow for easy access to internal components without disturbing the inlet/outlet connections. Additional accessories such as cleanout doors and drains allow ease the burden on maintenance personnel.

Sensor systems and controllers are another add-on feature that can maximize efficiency and output, minimize power usage and energy costs, and reduce long-term operating expenses and downtime. Intelligent transmitter nodes send information both on a scheduled periodic basis and when important changes are detected, ensuring that potential fan and system upset conditions are properly identified and managed. Customers can work with their representative or a nyb system engineer to determine the appropriate monitoring devices for their application.

About The New York Blower Company

The New York Blower Company is a leading manufacturer of premium-quality fans and blowers for the industrial marketplace. Since 1889, nyb has designed and manufactured products for the most demanding commercial and industrial applications including axial and centrifugal fans, custom engineered-to-order fans, and replacement parts for retrofits and rebuilds for multiple brands. Industries including agriculture, foundry, petrochemical, railroad and more rely on New York Blower for individual, flexible, customized solutions that meet specific requirements for unique applications. For more information, visit www.nyb.com.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.

![Why Enhanced Geothermal Energy Could Be Your Next Smart Investment [2025 Guide]](https://b1006343.smushcdn.com/1006343/wp-content/uploads/2025/06/Why-Enhanced-Geothermal-Energy-Could-Be-Your-Next-Smart-Investment-2025-Guide-500x280.jpg?lossy=2&strip=1&webp=1)