When I retired from the American Petroleum Institute (API) in May of this year, I decided to write a retrospective, having worked in the oil and gas industry for almost 40 years. In that time, I have had the opportunity to witness many changes in the culture, technologies and impacts due to U.S. economics and geopolitical circumstances.

I began my career in the oil and gas in 1979 with Chevron USA, working in the New Orleans, Louisiana, office as a graduate civil engineer, working in a special upstream group, which designed and built offshore oil and gas platforms and production facilities for the Gulf of Mexico (GoM). When I started with Chevron, the Iranian revolution had just occurred, starting the 1979 oil crisis that doubled the price of crude oil. Just six years earlier, the Arab oil embargo had caused a nearly 300 percent increase in the price of crude oil. As a result, in the early 1980s, the U.S. administration and American oil companies began an intense effort to find new oil and gas reserves. The GoM became a target of intense exploration.

As a woman engineering student, I entered college shortly after Title IX was enacted in 1972. I believe this act afforded me the chance to attend engineering school. When I attended Vanderbilt University in 1975 there were 25 percent women in my civil engineering class. When I went to work for Chevron four years later, there was only one other woman engineer in the New Orleans office. I was also the only woman out of about 10 engineers in my group. Being the lone woman, I was aware of the potential problems of being an anomaly and, while I encountered some bias, I got along with my male colleagues and bosses for the most part.

While in the New Orleans office, I learned about the intense effort it took to design offshore platforms and facilities for the Gulf of Mexico as the platforms were designed to withstand a Category 5 hurricane. After a few years at Chevron, I had the opportunity to witness the first dynamically positioned, floating production platform in the GoM, working in over 1,500 feet of water, using subsea wells. In 1979, the deepest water fixed platform was in just over 1,000 feet of water and engineers were looking into alternatives to drill and produce in deeper and deeper water. Today in 2020, the technology has developed such that deep-water drilling and producing are plausible with fixed platforms in over 3,000 feet of water and up to 10,000 feet of water using floating structures. This shows just some of the innovation and capability of the engineers in the industry.

During my career, I witnessed many downturns and upturns. These economic changes were usually a result of the changes in the price per barrel of crude oil and U.S. recessions. During the oil boom of the early 1980s, as the industry was hiring a lot of petroleum engineers, I worked in the Chevron corporate office in San Francisco. However, due to a U.S. recession in 1982, I witnessed my first downturn, as the hiring of engineers slowed dramatically. I was transferred back to New Orleans to continue working on offshore platforms.

In 1986, the industry faced another downturn as oil prices fell from $30 to $10 a barrel. This was the worst downturn I witnessed in my career as the economies along the Gulf Coast almost collapsed. Chevron laid off over 20 percent of its engineers and I remember touring south Louisiana and seeing offshore drilling rigs stacked in shipyards. It was an unsettling experience and I was sad to see many colleagues out of work, although I was learning this was part of working in oil and gas. I also learned that the community is tight knit and most of my friends were always able to adjust to the changing economics and find new jobs.

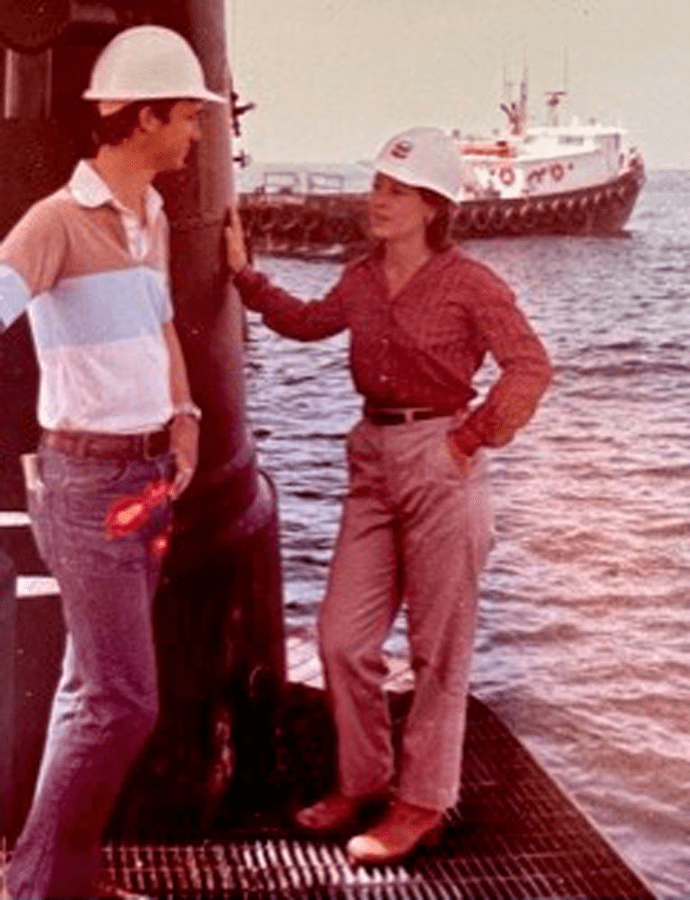

During my 13-year career with Chevron, I had the chance to go offshore for platform installations, drilling rig installations and to work on production facilities. I frequently took a helicopter, which in the early 1980s were often helicopters from the Vietnam war and, many times, the pilots had been pilots in the war. I also took crew boats, sometimes for as long as six hours. When I worked on the rig, I was often the project engineer or project manager. I was usually the only woman on the rig and in the 1980s there were no separate rooms for women and I usually displaced the rig’s company man from his room.

As the project engineer, I had to direct the contractor or foreman. He usually listened to me, but sometimes I was passed over and he perhaps looked to my male counterpoint for solutions. This was bothersome and affected my confidence and self-esteem. Back in the office, while I was getting praise from my bosses and good performance evaluations, some of my male peers thought I was being given special treatment because I was a woman. This presented another type of predicament as it wasn’t really discrimination, but a different kind of bias that was harder to deal with.

In 1992, there was another recession in the U.S. and I took an early retirement package from Chevron to attend SMU graduate business school in Dallas.

After SMU, I eventually accepted a position with the American Petroleum Institute in Washington DC. API was founded in 1919, mainly to develop standards for oilfield equipment as part of the WWI war effort. Today API is well known internationally for its standards, certification programs that certify oil and gas equipment, and advocacy and policy that promote a safe and viable U.S. oil and gas industry.

During my more than 22-year career with API, again, I met some of the brightest engineers and scientists, not only in the U.S., but worldwide. As audit manager for the certification program, I was fortunate to travel internationally and witness audits of manufacturers of oil equipment such as valves, line pipe and derricks. These manufacturers ranged from small outfits to huge plants. The quality control measures in place were detailed and complex.

While at API in Washington, I also worked with many more women, who were placed in high positions at API, including advocacy, communication and economics. I was fortunate to be able to work for a woman for the first time starting in 2007 when I moved to work with the Standardization Committee on Petroleum Measurement. API has over 800 standards that cover all three segments – upstream, midstream and downstream. Two hundred of those standards cover measuring the quantity and quality of crude oil and petroleum products for custody transfer. These standards use complex chemical theories to determine oil and gas properties and complex equipment, such as meters and computers to sample oil and gas, and determine a quantity being transferred.

In my work with the API measurement committee, we worked under strict guidelines set forth by the American National Standards Institute (ANSI) for standard development. These guidelines involve openness and require a balance of users: manufacturers, academia and government agencies. The committees work under strict guidelines using Robert’s Rules of Order. Like my experience with Chevron, most of the committee members were men; however, I encountered more women on the committees than I had working in the oil field.

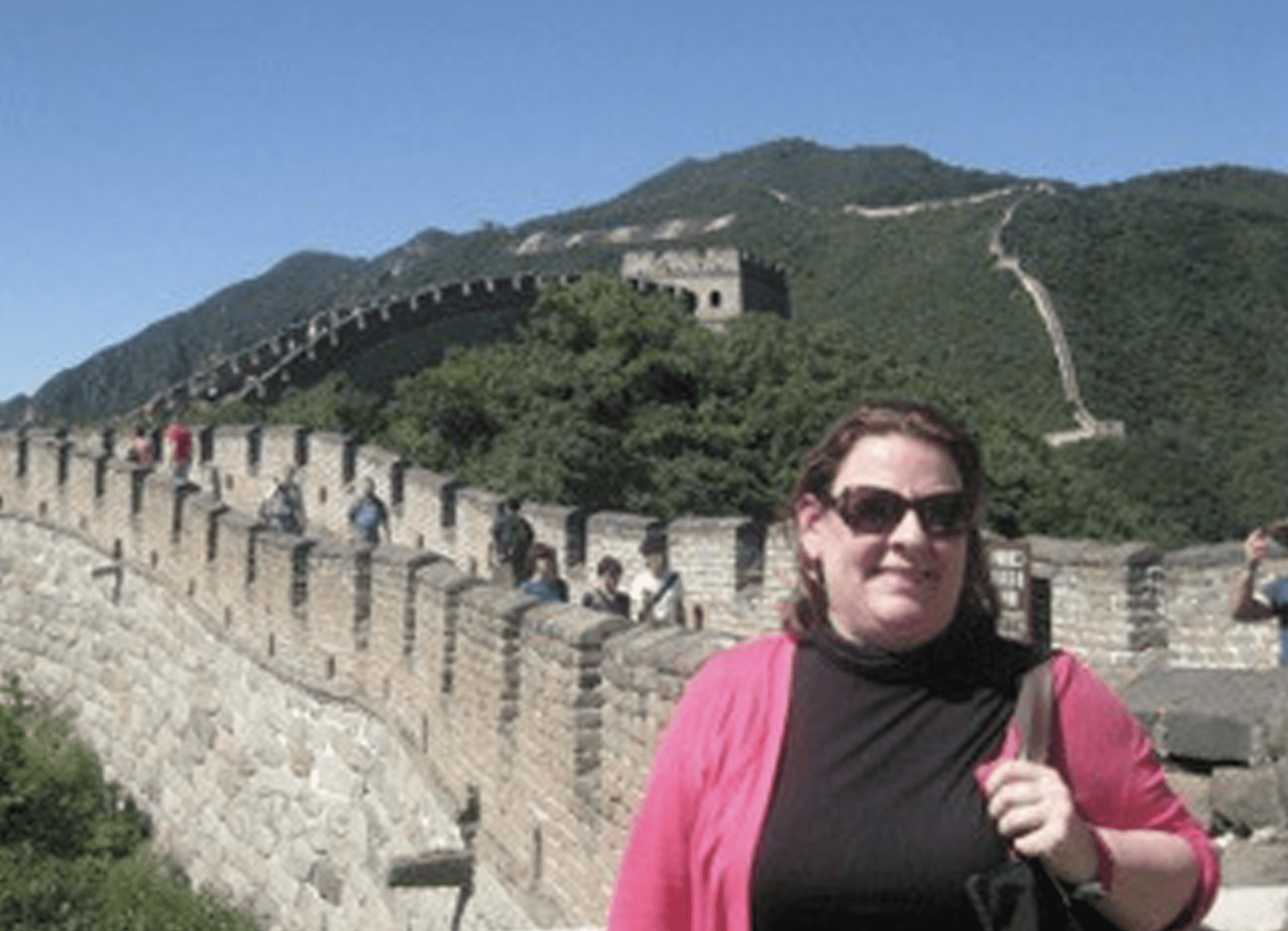

As API standards are global, I traveled to several countries in Europe, South America and Asia to promote them. This broadened my knowledge of a global oil and gas industry and introduced me to more amazing engineers and scientists.

On a few occasions, I had the opportunity to do advocacy, primarily with the Environmental Protection Agency (EPA) and the Department of Interior (DOI), Bureau of Land Management (BLM). Both government agencies were interested in the content of API standards because of their impact on safety and measurement of oil and gas. The government employees were pleasant to work with and, while they looked out for the government’s interest, they liked collaborating with members in the industry to find the best solutions.

Moving on to the 21st century and now being retired, I have had some time to think about where the culture and technology are now and where they are going. Today, you find many women on boards and in leadership roles, at both oil and gas companies and service companies.

Also, I believe the industry can solve the problems it faces with regard to climate change. API is now leading in measuring and reducing emissions, and in carbon capture. The oil and gas industry is taking on the issue of climate change as it has with past challenges through innovation by the best engineers in the world. I am confident these problems will be resolved and I hope the general public can learn to appreciate the work the people in the oil and gas industry do.

Sally Goodson retired from The American Petroleum Institute (API) in May of 2022. She spent over 40 years in the natural gas and oil industry, working for Chevron Corp. as an engineer responsible for the design, construction and installation of offshore oil and gas platforms, and API, providing technical expertise for upstream and midstream segments. Goodson supports and volunteers for the Salvation Army and participates in STEM events.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.