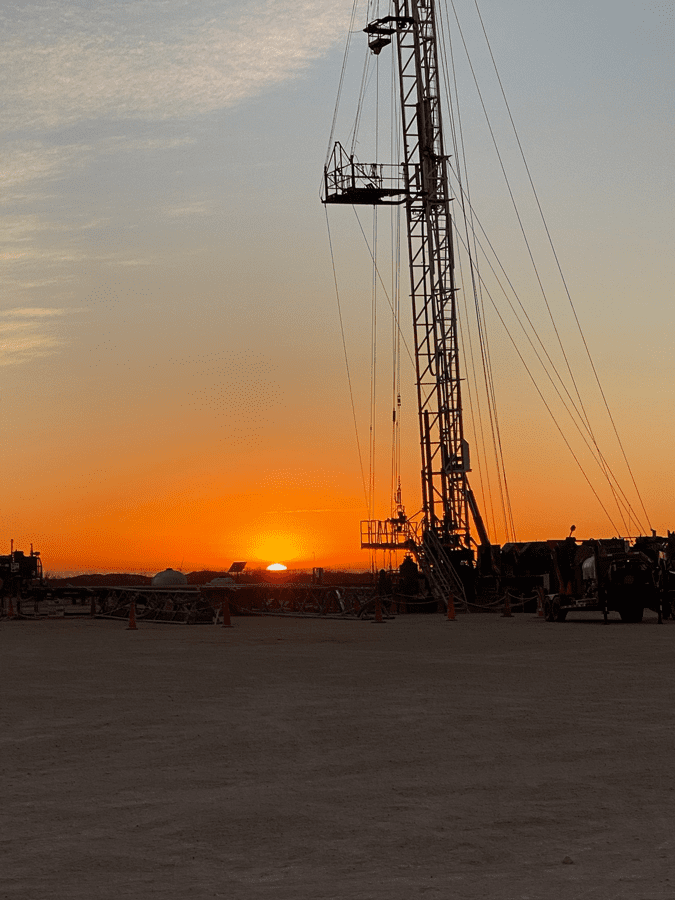

4:45 a.m. Wake and shower, pack a lunch and drive out to location. Our rig typically moves every three to four days to a new well on a new location. The wells we work on are usually in the same area which is about an hour from the camp we stay in. Seventy percent of the trip is down a bumpy ass dirt road sometimes resembling more of a cow trail than a road. I usually arrive on location at 6:00 a.m. and get set up for the day. West Texas has the best sunrises and sunsets. Even though it’s dark when I arrive on location, that sunrise is a great start to the day.

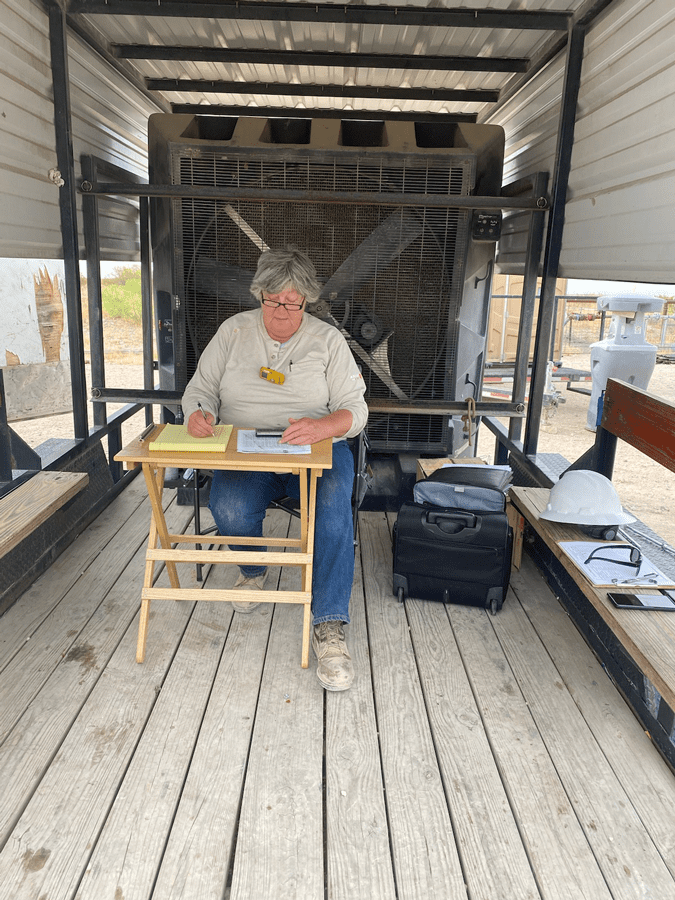

7:00 a.m. A five man crew and I start the day with a morning meeting to discuss the workload for the day, along with the hazards and mitigations. This meeting is held on a tailgate or in an open-sided cooling trailer. Each day brings a different challenge. No well is the same. Today’s plan is pulling a gas lift completion due to a suspected hole in the tubing. The well is no longer producing hydrocarbon, so it is our job to get the well repaired and back online.

The goal of this meeting is to make sure everyone knows the plan and has the knowledge and skills to perform the work. When we have a new crew member (aka “green hand”), they are assigned a mentor. The mentor is a more seasoned crew member and is responsible for showing the new employee how we safely get the work done.

We all work rotational schedules: I work two weeks on/two weeks off. My crew works three weeks on/one week off. Two crews support our rig. There has been a lot of turn-over in the oil industry and we are fortunate to have retained most of the original crew. I have had the same rig and same crews for almost three years. The consistency of the rig and crew is truly a blessing.

7:30 a.m. We inspect the equipment and get the wellbore pressures. If the well has pressure on it, we bleed the gas head off to an open top tank and then bullhead a kill volume. This volume varies in quantity based on the pressure seen on the well. The volume is usually between 50 and 150 bbls of 10 ppg brine. This puts the well in a static state and we can safely go about our work. The well is monitored to ensure it stays in that static state. If conditions change and the well pressures up, we pump another kill volume.

Wells will talk to you if you will listen. Some wells are easy and predictable to kill, and others are not. Each well has its own characteristics. Multiple wells on the same location often require different kill volumes and kill weights. When the well is in a static state, aka “dead,” that is our window of opportunity to work on the well. We do not work when the well is live or producing hydrocarbon.

8:30 a.m. The well is static and equipment inspections are done. We then pause at the worksite and go through a checklist prior to starting the work. We pause at the start of an operation and when the plan changes. This makes sure we are all on the same page. The crew is an active part of our daily work plan, which can change due to unforeseen conditions such as equipment failure or bad weather.

Everyone on location has a stop work responsibility: Meaning if you see something that does not look right or is not understood… just stop and we will talk about it. Not every crew member has the same level of experience or expertise, so we learn from and teach each other.

8:45 a.m. Install a back pressure valve in the tubing hanger, and nipple down (remove) the production tree and nipple up (install) the blowout preventers (BOPs). The back pressure valve is a check valve that is installed in the tubing hanger and isolates the well allowing for the safe removal of the production tree. The BPV is removed and the BOPs are tested to the rated working pressure (5000 psi).

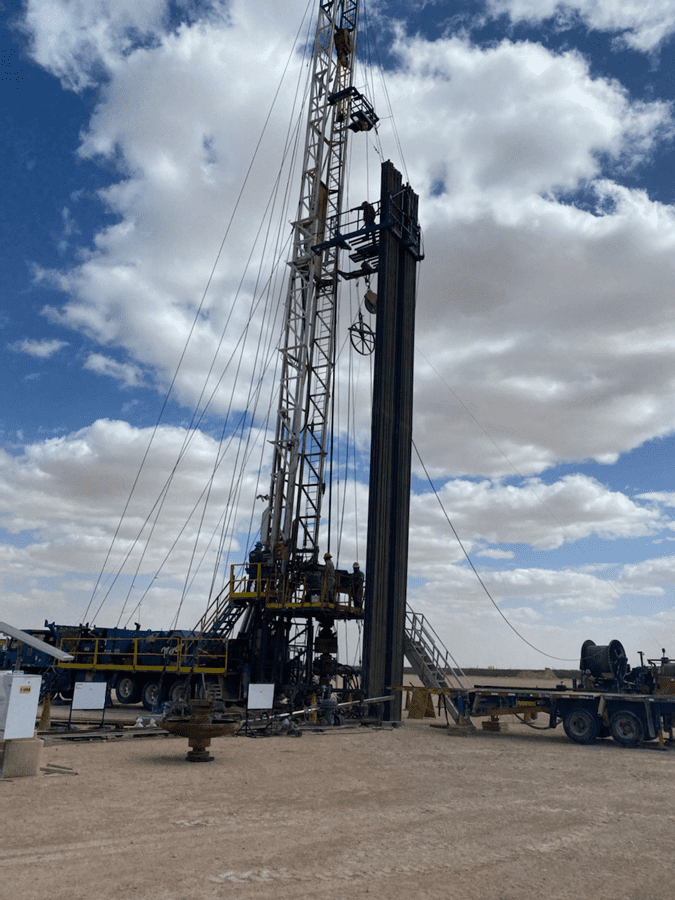

10:45 a.m. Move the rig onto the well, raise the mast and secure guy wires. Rig up the tubing floor and tools. Inspect the rig and derrick. Break for lunch (30 minutes). The crew also takes breaks as needed during the day. The summer temperatures are often above 105 F and we work in the hot sun without much shade or breeze. It’s important to stay hydrated and watch out for each other in the heat.

12:00 p.m. We release the tubing hanger, unlatch from the downhole packer, and lay down the tubing hanger. This well produces through the tubing and the hanger secures it place in the well head.

12:30 p.m. We begin pulling the tubing out of the well. This well has been producing for three years, which is a good run. We scan the tubing out of the well to look for holes and wear. We pull the tubing normally in doubles (64’ lengths) and rack it back in the derrick. The good tubing will be rerun and the tubing that does not pass inspection will be replaced with new or refurbished tubing.

In this well, we are laying down all the tubing and will run back in with a fresh string of inspected tubing and new gas lift mandrels. We manage well control during this operation by filling the hole at intervals as the pipe is pulled with a weighted fluid. This keeps the well in a static state. We have 317 joints (10,228’) of tubing in this well to lay down. Since we are laying down all of the tubing, the trip out of the hole takes longer.

5:30 p.m. All the tubing is out of the well. We close the blind rams and casing valves, isolate our pump and fluid tanks. This secures the well for the evening. Our rig works daylights only.

6:00 p.m. Depart location and head back to camp. Our camp is a house trailer that we typically share with another supervisor. I do not stay in the same camp as the rig crew; however, the travel time is about the same. It will take me an hour to get back to camp. The West Texas desert is beautiful even in the heat of the summer. We see all kinds of wildlife: burrowing owls, coyotes, wild hogs and hawks. I do love my work and teaching the younger hands the safe and efficient ways to work. Tomorrow is another day, and we will run a new string of tubing back in the well. This type of job typically takes three days and then we move to another well and start again.

I have the best job in the world and am blessed with great crews and co-workers.

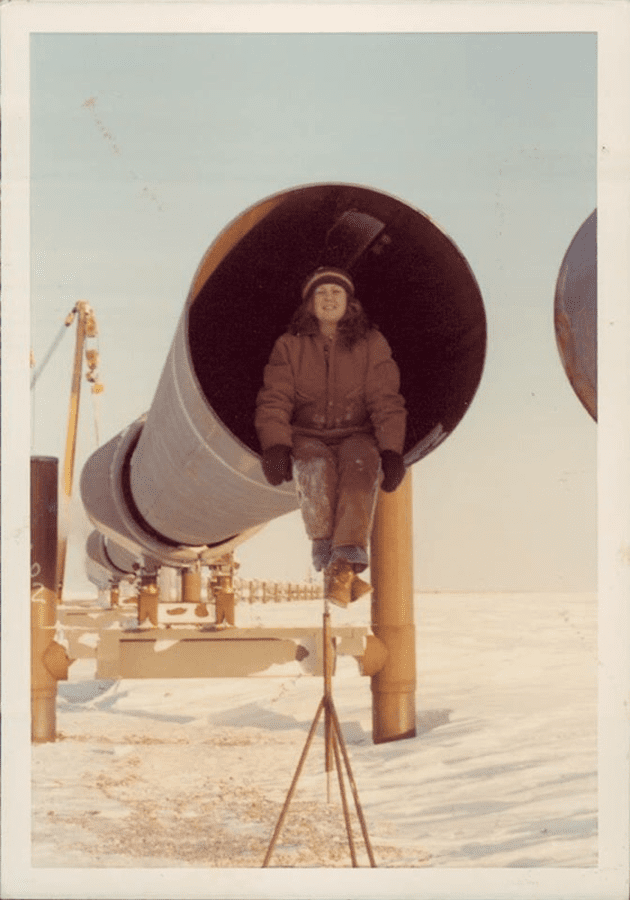

Joey Roth currently works as a well intervention supervisor for ConocoPhillips. She started in the oil field as a truck driver on the Trans-Alaska Pipeline (TAPS), then went to work as a roustabout in Alaska’s Cook Inlet as a roustabout in 1979. Roth worked her way up to a drilling foreman for Shell Oil Co. She then decided to get her engineering degree and has had a long career as a senior drilling engineer, working for major oil and gas companies such as Amoco, Schlumberger, Vastar/bp, Hunt and Shell Intl. E&P. Roth holds a Bachelor of Science, Mining and Mineral Engineering, from Colorado School of Mines.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.